Electron beam technology is multifaceted. For example, with our product witafilm: It can be used to create a wide variety of surfaces for furniture, facades, laboratory tables, doors, and kitchens. The technology is equally suitable for the food industry and for technical films. Witafilm is premium, extremely robust, appealing, and long-lasting.

Whether WITA as a release film or our EBC technology as a direct coating: after further processing, the finished products have significantly optimised properties. Depending on the industrial sector, this can be, for example, a particularly high-quality furniture surface with a soft-matt look and feel or a food-safe surface for a kitchen worktop.

All Taubert product lines follow the same principle: EBC technology cross-links the material deep into the texture. This makes it much more efficient – and optically refined depending on the intended use and requirements. .

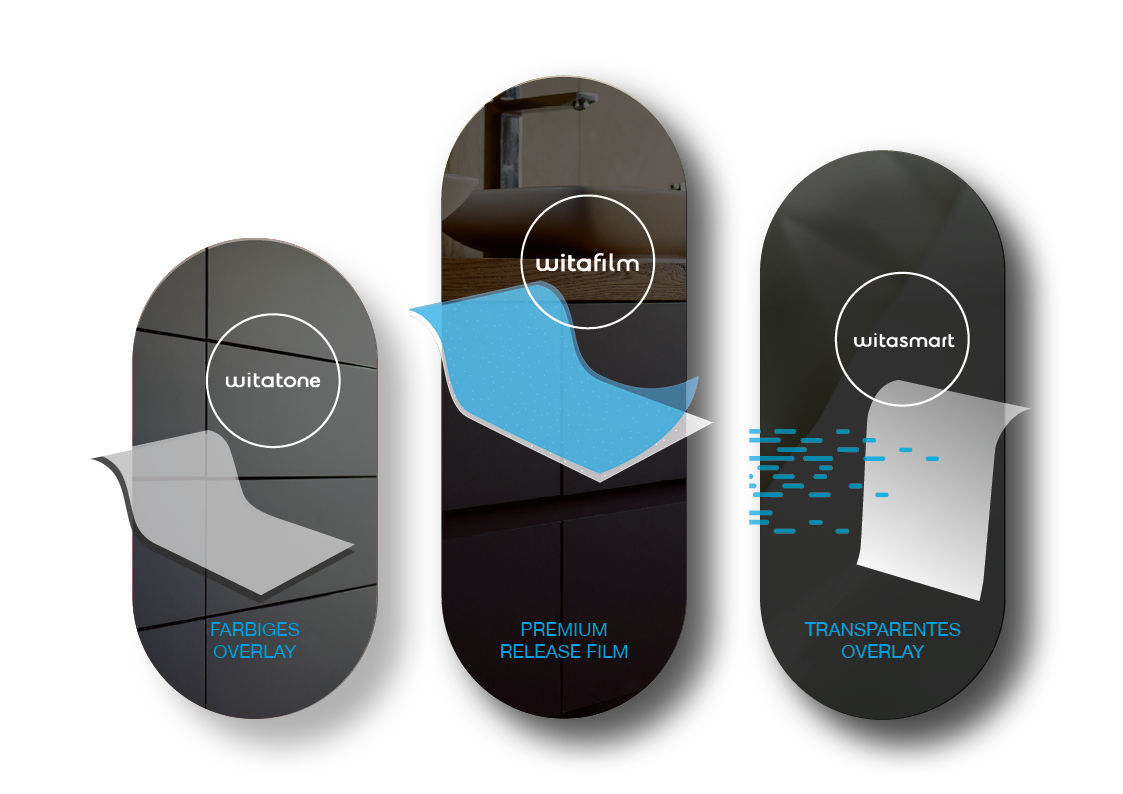

The look of the finished product after further processing varies from extremely matt, soft, and rubber-like to high-gloss. EBC product variants: WITAfilm, our premium release film, is a semi-finished product that enables the finest textures to be transferred to a wide variety of end product surfaces, giving them optimum properties in terms of look, feel and functionality. We are currently developing variants of a direct coating that is bonded to the surface of the end product. It is also possible to optimise existing film products with the use of our EBC technology, for example for use in the food industry.

The WITAsmart soft touch surface is a brand new addition to the range. Both are characterised by their velvety feel and extremely matt appearance. Find out more about WITAsmart now at www.laminate.de.

The smartsurface: The result of our technology is a sustainable, highly cross-linked surface that withstands the greatest wear and tear. It is scratch resistant, versatile, environmentally friendly, and low odour.